This is a Made to Order product. Specifications Nominal Chemical Compositions Brass and Bronze Standard Casting Alloys Chart of Specifications Military Current C-22229 Gr2 C-15345 Gr3 C-22229 Gr9 C-22229 Gr8 C-22229 Gr7 C-22229 Gr4 C-22229 Gr1 B-16541 C-15345 Gr10 C-15345 Gr12 C-22229 Gr3 C-22229 Gr5 C-15345 Gr13 C-22229 Gr8 C-20159 Gr2 C-20159 Gr1 C-15345 Gr7 C-17112 Military Superceded B-16444GrA.

Food Grade Oil Oilite Impregnated Copper Sae 841 Brass Bronze Bushing With Graphite Inserts For Electric Fan Buy Oil Bronze Bushing Oil Impregnated Bushing Brass Bushing For Electric Fan Product On Alibaba Com

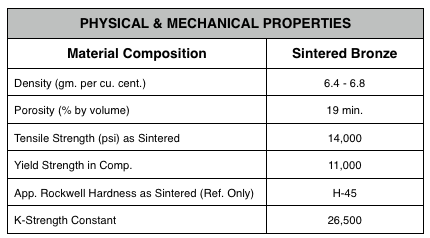

Yield Strength in Comp psi 11000.

Sae 841 chemical composition. Value in metric unit. Physical and Mechanical Properties for SAE 841 Bearings. This alloy is not available as an Off-the-Shelf product but is available as a special casting only.

There are as many as 400 different copper and copper alloy compositions loosely grouped into the categories. Value in US unit. Atlas Bronze offers C92700 Leaded Tin Bronze SAE 63 in Centrifugal Castings and Sand Castings.

New grades will be considered based on the grade meeting a SAE grade designation and chemistry having a minimum production or consumption of 225 tonnesyear 250 tonsyear and has the sponsorship of at least two individual users or producers. SAE 660 is one of the most widely used alloys on the Bronze range mainly due to its versatility as a medium range Bronze that make it suitable for many applications. Chemical Composition Limits Weight Cu.

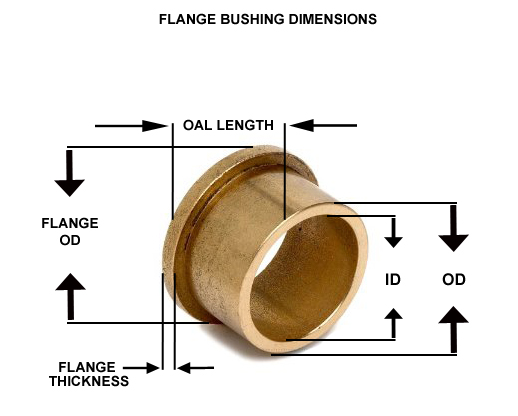

X 2 IN Overall Length SAE 841 Powdered Metal Bronze Sleeve Bearing. Elongation in one inch 1. Ni value includes Co.

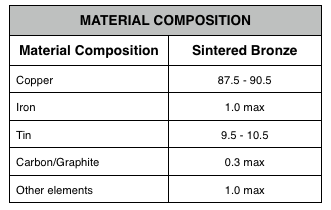

NoteCuSumofNamedElements990min CHEMICALCOMPOSITION max unless shown as range or min Cu 1 Al Fe Pb Mn Ni2 Sn Zn. In determining Cu min Cu may be calculated as Cu Ni. Chemical Composition nominal composition.

One of the finest powder metal bearings on the market. SAE J461 J462 JoiningTechnique Suitability Machinability Rating 30 C86200ManganeseBronze C86300ManganeseBronze 1. Density gm per cu.

Oilite self-lubricating bearing products are made by a powder metallurgy process allowing close control on the manufacturing process. It is used in appliances business. Chemical Composition- Copper 87-90 Tin 8-9 Iron 10 Max Carbon 01 other elements less than 01.

Sintered Bronze SAE 841 Bearings Properties. Oilite Bronze Bearing Alloy - SAE 841 Categories. The following table lists the principal alloying element for four of the more common types used in modern industry along with the name for each type.

SAE 841 Bronze PM 50000 SAE 863 Fe PM 35000 60 Cu 40 Fe PM 35000 SAE 850 Fe 30000 High Tin Babbitt 89 30000 Low Tin Babbitt 10 18000 ToughMet3 Unlubricated 17000 GraphiteMetallized Brgs15000 Carbon 15000 Low Tin Low Pb 6 Babbitt12000 Comparison data from Bunting Bearing Corp. During operation oil impregnated bronzes have a proven record of. Cuin ksi degrees F BTUsqftfthrdegrees F 68 degrees.

SAE 841 Sintered Bronze - Oil Impregnated. This Bronze has good hardness. New steel compositions will be considered as Potential Standard PS steels based on the guidelines in SAE J1081 until such time as production of.

Porosity oil by vol 190 min K Strength Constant 26500 psi. SAE 841 SINTERED BRONZE Chemical Composition Mechanical Properties Benefits - Tight tolerances allow for reduced shaft clearances and better press fits. By using a proprietary blending and sintering process this gives us a uniform grain structure and spheroidized porosity which results in superior strength lower coefficient of friction and a uniform oil coating of the mating shaft.

- Long lasting self lubrication provides an oil film for smooth start-ups - Elimination of oil groove and oil hole - Can be re-oiled when dry. SAE 841 875-905 None None 1 95-105 None None None None None None 03 Carbon ALLOY NOMINAL DENSITY MODULUS OF ELASTICITY MELTING POINT OR RANGE THERMAL CONDUCTIVITY ELECTRICAL RESISTIVITY TEMPER HARDNESS ULTIMATE TENSILE STRENGTH YIELD STRENGTH ELONGATION lbs. They contain large interconnected pores to channel lubricants to the areas between shaft and bearing.

Copper high copper alloy brasses bronzes copper nickels coppernickelzinc nickel silver leaded copper and special alloys. C090 Mn075 P004 max S005 max. The method in which the material is cast will depend on your size specification and desired quantity.

X 15045 IN OD. ASTM - B-438-05 Grade 1 Type II.

China Sae 841 Sintered Bronze Astm B438 Round Bars China Bronze Rod Oil Copper

Sae 841 Sintered Bronze Solid Bar Stock Atlas Bronze

Sae841 Astm B438 Sint A50 Sintered Bronze Bearings Oil Impregnated Sino Bronze Co Ltd

Ff 838 1 Oil Impregnated Bronze Flanged 3 4 Id X 7 8 Od

Sliding Food Grade Sae841 Bronze Oil Bushing Sleeve Bearing Buy Bronze Oil Sleeve Bronze Sleeve Bearing Sae 841 Bushing Product On Alibaba Com

China Sae 841 Sintered Bronze Astm B438 Round Bars China Bronze Rod Oil Copper

Sintered Bronze Oil Impregnated Self Lubricating Sleeve Bearings Good Corrosion Resistance For Sale Valve Bushing Manufacturer From China 109155644

China Sae 841 Sintered Bronze Astm B438 Round Bars China Bronze Rod Oil Copper

Sae 841 Sintered Bronze Oil Impregnated Bronze Aviva Metals

Sae 841 Sintered Bronze Solid Bar Stock Atlas Bronze

Ff 312 Oil Impregnated Bronze Flanged 1 4 Id X 3 8 Od X 1 4 Oal X 15 32 Flod

Food Grade Oil Oilite Impregnated Copper Sae 841 Brass Bronze Bushing With Graphite Inserts For Electric Fan Buy Oil Bronze Bushing Oil Impregnated Bushing Brass Bushing For Electric Fan Product On Alibaba Com

Sae 841 Graphites Mos2 Sintered Bronze Bearings Oil Impregnated Sino Bronze Co Ltd